[This dissertation was completed as part of the work for an MA in Archaeology undertaken at Birkbeck College, University of London between October 1999 and September 2001.]

Abstract

In the past Reigate Stone was used in many important buildings in and around London. Based on field investigations; standing buildings studies; historical documents; and archaeological, and other, reports this dissertation examines where and how Reigate Stone was quarried; when, where, and for what it was used; and how it was transported from quarry to building site. It shows that

Reigate Stone was used from the Roman period until the 19th and 20th centuries; that it was mainly used in Royal, monastic and other church buildings; that it was quarried underground from a narrow strip of the southern slopes of the North Downs measuring c.16km east-west; that many of the quarries survive; and that it was transported by road to the River Thames and then by water.

1. Introduction

I find, after the Conquest, all our Artists were fetched from Normandy: they loved to work their own Caen-stone ... This was found expensive to bring hither, so they thought Rygate-stone in Surrey, the nearest like their own ...

Christopher Wren, 1713

1.1 General.

The oldest and most prestigious buildings in many of the world’s great cities are frequently those built of stone. To ensure long life the stone used must be durable and capable of withstanding the often polluted urban atmosphere. To produce fine architecture it helps if the stone is fairly easily worked and readily carved. Some cities are fortunate in being located near sources of stone which combine relative ease of working with reasonable durability. London is not so lucky. It has no real building stones at all in its immediate vicinity and its builders have, in the past, had to make pragmatic compromises between the accessibility, durability and workability of different types of stone.

The use of Reigate Stone in buildings in and around London is an example of just such a compromise. As its name suggests, this stone comes from the area around Reigate which is located about 30 km south of London. In terms of distance it is, therefore, one of London’s more accessible building stones. However, it is fairly soft. Whilst this makes it easy to work, it also contributes to its poor weathering properties. Nevertheless, in an area with a dearth of good building stones, lack of durability was sometimes of secondary importance. For many centuries it was widely used in the south-east of England; often for highly visible, decorative work in some of the most prestigious buildings in the country. Reigate Stone is, therefore, more important in terms of the archaeology of buildings than might be expected just from consideration of its intrinsic qualities as a building material.

1.2 Outline History of Use

In the past it was widely accepted that Reigate stone was “not found in Roman contexts” (Westman,1994,3.3.4). Recent archaeological excavations have, however, yielded a small number of finds of Reigate Stone from securely dated Roman levels, including some from pre-Boudiccan levels in London (Drummond Murray & Thompson, in prep.) Evidence from standing buildings and excavations shows that there was also some use of Reigate Stone during the Saxon period. However, the first major exploitation of Reigate Stone occurred in the medieval period. This reflected the increasing number of masonry buildings being erected, principally for the Crown and Church. Royal and religious demand for the stone continued into the 16th century. Following the dissolution of the monasteries one source of demand virtually disappeared and sometimes even helped meet the demand from the other source, as when Henry VIII’s Nonsuch Palace was supplied with Reigate Stone from the dissolved priory at Merton (VCH,ii,p278). In the next couple of centuries changes in fashion and improved supply of better building materials resulted in Reigate Stone being less widely distributed, although a lot of it was used in the rebuilding of St Paul’s following the 1666 Fire of London. The end of the 17th century also produced the first eye-witness accounts of Reigate-stone quarries (Aubrey,1718). Evidence for its use as a building material in the 18th century is rare but, because of its refractory properties, it continued to be used for the linings of kilns, ovens and furnaces (VCH,ii,p278).

During the Victorian era the fashion for whitened doorsteps created great demand for the softest form of Reigate Stone, usually called ‘Hearthstone’. This was wetted and rubbed on the step, leaving a white deposit. However, even during the 19th century Reigate Stone was still used for building; it was even considered (but rejected) for use in rebuilding the Houses of Parliament (Barry,1839). The last days of the industry were devoted solely to hearthstone production, an activity which only finally ceased in the 1960s.

1.3 Nomenclature.

The name ‘Reigate Stone’ is widely used by archaeologists (e.g. Westman,1994) and building historians (e.g. NMR), although sometimes the less definite ‘Reigate-type stone’ is used. This may be because it is known that the stone was also quarried in other parishes near Reigate and it is not possible to determine petrologically the precise source of archaeological specimens (deDomingo,1994,p243).

However, whilst contemporary historical documents sometimes name the parish of origin precisely - e.g. “Regate stone otherwise y called Mestham stone” (Eton Coll. Building contract c.1453 in Salzman,1967,p527) - such documents also frequently used the term generically. Hence we find in the London Bridge accounts for 1461 “for 47 loads of stones called Reygateston at 20d the load at the quarry of Maistham 78s4d” (Harding & Wright,1995,p126).

In this account the term Reigate Stone is used in this generic sense. The extent of the area to which it can be applied is discussed in sections 1.4, 2.1 and 3.1 below. Reigate Stone is also sometimes called ‘Firestone’. This name has been used not only when the stone has been used as a refractory (see 1.2 above) but occasionally when it has been used as building material. For example, the NMR contains 3 listed building records where the main material is Firestone compared with 31 entries where the main material is Reigate Stone.

As noted above, ‘Hearthstone’ is a similar but softer material to Reigate Stone and is found inter-bedded with it (see 1.4 below). The term usually refers to the material used for whitening steps. However the context needs to be looked at carefully since a hearthstone may also be ‘a flat stone forming a fireplace’ (QED); such a hearthstone would be more likely to be made from the harder Firestone.

The term ‘freestone’ is also sometimes applied to Reigate Stone (see e.g. VCH,ii,p278). This is, however, not a term which is exclusive to Reigate Stone but is also applied to other building stones, particularly limestones, which “can be freely worked with hand tools in any direction” (Clifton-Taylor&Ireson,1983,p17).

1.4 Outline Geology.

Reigate Stone comes from the geological formation called the Upper Greensand. Although the Greensands - Upper and Lower with the Gault Clay between them - are widespread throughout south-east England - see Fig 1 - only a small area appears to have provided Reigate Stone. According to Fitton, writing in 1827, “Merstham occupies nearly the middle line which has been worked upon for firestone [=Reigate Stone]; the extreme points to which the quarries have extended of late years being near Godstone on the east and Buckland Green on the west” (quoted in Jukes-Browne, 1900,p97).

This area is also shown on Fig 1. Modern authors agree with the eastern limit but extend the western limit a little to Brockham (see e.g. Sowan,1975,p575). However, the westernmost quarries in Brockham and Betchworth may all be late 19th century and have been worked solely for hearthstone (ibid.,p588). In fact Hawkins, referring specifically to Brockham in 1879, writes about “a tunnel which is excavated entirely in the Hearthstone, no attempt being made to work the underlying Firestone” (quoted in Jukes-Browne,1900,p100).

Geology was an important factor in limiting quarrying to this area. The dip of the Reigate Stone beds increases from east to west. At Brockham it is over 21½º, compared with 4-9º over the rest of the area (Jukes-Browne,1900,p100). East of Godstone the Reigate Stone formation “thins to a metre or so of economically valueless sand” (Sowan,1975,p575). The type of quarrying used to exploit Reigate Stone (see sections 2.1 and 2.2 below) is impractical if the bedding is thin or steeply dipping.

Commentary and tables in Jukes-Brown present a simple model for the relationship between the hearthstone and firestone beds with the former overlying the latter. The precise thickness and character of the stone which could be exploited varied from quarry to quarry but the details from Merstham shown in Table 1 above are reasonably typical. However, Sowan (1999,p5) reports that there are other descriptions which “indicate that building stone and hearthstone beds alternated in the underground working faces.” Such individual beds are not readily detected by normal field inspection and recent geological studies indicate that, in fact, “the beds exploited ... appear to consist of lenticular masses of good building [i.e. Reigate] stone which would weather well, intercalated with similar masses of inferior stone [i.e. hearthstone] fit only for use as a mineral pigment” (ibid.p6).

Commentary and tables in Jukes-Brown present a simple model for the relationship between the hearthstone and firestone beds with the former overlying the latter. The precise thickness and character of the stone which could be exploited varied from quarry to quarry but the details from Merstham shown in Table 1 above are reasonably typical. However, Sowan (1999,p5) reports that there are other descriptions which “indicate that building stone and hearthstone beds alternated in the underground working faces.” Such individual beds are not readily detected by normal field inspection and recent geological studies indicate that, in fact, “the beds exploited ... appear to consist of lenticular masses of good building [i.e. Reigate] stone which would weather well, intercalated with similar masses of inferior stone [i.e. hearthstone] fit only for use as a mineral pigment” (ibid.p6).

This more complex view of the geology may explain why, despite sophisticated petrological analysis, archaeological specimens which were “firmly identified as Firestone from the Reigate area” “could not be sourced accurately” [i.e. could not be identified as coming from a particular quarry] (de Domingo,1994,p243). To match archaeological samples to distinct, laterally wide-spread, beds would be difficult enough; to match them to different individual lenses would be practically impossible.

2. Exploitation

2.1 Locating the Quarries.

Today the word ‘quarry’ generally conjures up an image of a large open-cast pit from which stone of all kinds is extracted. In the past it had a meaning which was simultaneously both more and less precise. “The word ‘quarry’ is derived from the Latin quadrare, to make square. Quadraria were places where squared stones were cut, which is another way of saying an excavation in beds yielding large ‘dimension’ or ‘block’ stone for all building and monumental purposes” (Stanier,1995,p9). It is not necessary for such workings to be open-cast; they can be underground quarries - ‘mines’ in modern parlance. Medieval and later documents which refer to Reigate Stone quarries use the word in this sense; there is no evidence to suggest that medieval and later quarries were other than underground. In the Reigate Stone quarrying area between Brockham and Godstone the Upper Greensand lies beneath the chalk and outcrops on the southern side of the North Downs.

The entrances to the underground quarries are generally located a short distance north of where the Upper Greensand outcrop actually comes to the surface. This is probably because natural weathering of the stone at, or near, the surface would tend to make it too friable for building purposes.

In comparison with open-cast quarrying the techniques used for underground quarrying (see 2.2 below) had relatively little impact on the surface. This presents difficulties when it comes to locating the quarries. Place name evidence can be a help: e.g. Quarry Farm (TQ352533), Quarry Hall Farm (TQ322532), Quarry Hangers (TQ322535), Quarry Dean Farm(TQ298539). However, many places in the quarrying area are located near relatively modern, large, open-cast, chalk pits and the antiquity of ‘Quarry’ names needs to be established before they can be taken as evidence of Reigate Stone working. Whilst the existence of these chalk pits can be confusing it was largely as a result of Croydon Council’s intention to use the pit near Merstham as a land-fill rubbish dump that local interest in the Reigate Stone quarries was aroused. In an attempt to determine whether there was a risk of contamination from the rubbish entering the ground water via the old quarries local caving clubs re-opened old workings, all of which had been sealed for decades and some of which had probably been sealed for centuries (Musto, 1969).

The knowledge gained from these re-opened quarries has provided the basis for much of the rest of what is set out below on exploitation. It also provides the most certain evidence for the location of the quarries. This has been supplemented by field walking, place-name studies (see above), and the study of old maps and documents and more modern local histories.

In general, documentary sources are of most use for quarries still being worked in the 19th century. However, at least one medieval document appears to give a fairly precise location for a Reigate Stone quarry: in a charter of 1218 Earl William de Warenne granted the canons of Waltham Abbey:-

“land in his vill of Reigate lying at the foot of the road to Walton on the Hill at the place called White Lamb and measuring one hundred and forty feet by seven hundred feet for a quarry ... for stone for building”

(Ransford,1989,p431)

A note in Surrey Archaeological Collections (Saaler,1994,87,p207) places ‘Witelamb’ at NGR TQ 2452, i.e. somewhere on Colley Hill. It is unclear whether this is based on precise knowledge of where White Lamb is located or is based on a sensible interpretation of the rest of the data in the charter, coupled with a knowledge that Colley Hill was certainly quarried in later centuries. However it should perhaps be noted that in 1217-18 Colley was held by one ‘Walter of Colley’ as a separate Manor within the honour of Reigate (VCH,iii,p237).

2.2 Quarrying Techniques.

2.2.1 Gaining Access.

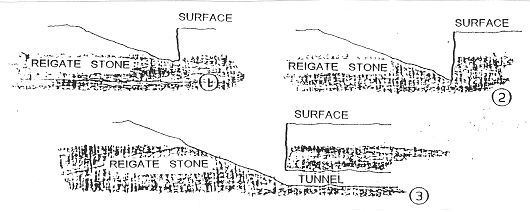

Access to the Reigate Stone beds through the chalk (see Fig 2 above) was achieved using a modified form of ‘adit or drift mining’. In adit mining, instead of sinking a vertical shaft and then striking out along the bed of rock, a tunnel is driven into the hillside where a bed of the material sought is found. The modification employed in Reigate Stone quarries was to dig a sloping trench downwards and forwards, through the chalk/chalk marl, until the Reigate Stone was reached - see Fig 3. Then quarrying commenced by driving tunnels into the rock, following the dip of the strata and ensuring that the “hard roof” stone (see Table 1) was left intact.

Particularly good examples of such entrance depressions can be found near the Chaldon/Merstham parish boundary. The woods called Bedlams Bank at TQ308537, for example, are growing in and around two entrance depressions each originally over 10m deep and about 100m long. One has the steeper side of its sloping trench at the west end of the woods and the other has its steep side at the east end, the more gradual slopes of both converge at the centre of the woods. These gradual slopes would have provided a route by which the cut stone could be finally hauled to the surface without the need for any special winding equipment.

Particularly good examples of such entrance depressions can be found near the Chaldon/Merstham parish boundary. The woods called Bedlams Bank at TQ308537, for example, are growing in and around two entrance depressions each originally over 10m deep and about 100m long. One has the steeper side of its sloping trench at the west end of the woods and the other has its steep side at the east end, the more gradual slopes of both converge at the centre of the woods. These gradual slopes would have provided a route by which the cut stone could be finally hauled to the surface without the need for any special winding equipment.

The fact that the quarries were worked down the dip of the rock, coupled with an appreciation of the surface geography indicated in Fig 2, provides one explanation for Reigate Stone being worked underground rather than from open-cast pits: the amount of unwanted chalk &c. which would have to be removed before reaching the 1.5m or so (see Table 1) of useful building stone would rapidly become excessive. When all such excavations were done entirely by hand it would have been particularly important not to waste effort digging out unwanted material. Also, by working underground, the economically valuable farmland above the quarries remained untouched. Farmland was further preserved by leaving underground all of the waste material excavated in the quarries. In the case of Reigate Stone quarries worked exclusively for building stone (i.e. pre-19th century workings) this waste included considerable quantities of hearthstone. The absence of obvious surface waste tips of hearthstone anywhere in the Reigate Stone quarrying area provides further support for the contention that it was always quarried underground.

Perhaps the strongest reason for believing that Reigate Stone for building purposes was always quarried underground comes from consideration of the nature of the stone itself. Clifton-Taylor has observed of limestone freestones (see 1.2 above) that:-

“While the stone lies in the quarry, the pores between the grains contain natural moisture. When it is lifted out, the moisture moves towards the surface of each block, and by the absorption of oxygen, the calcite within the stone gradually crystallizes and hardens. So limestone can be worked and dressed much more easily while still ‘green’: that is to say, when it has just been quarried. Masons, of course, have always known this, even if they did not fully understand the chemical changes that the stone was undergoing. They called the pristine dampness ‘quarry sap’.” (Clifton-Taylor&Ireson,1983,p26#)

Whilst, strictly, “Reigate stone is neither a limestone nor a sandstone; nor ... a calcareous sandstone” (Sowan,1999,p5) it does contain sufficient calcium carbonate (about 45% according to tables in Jukes-Browne,1900,pp326-7) for a similar process to take place. Indeed, Jukes-Brown himself notes (p420) that Reigate Stone “hardens on exposure to the air, if kept undercover and protected from the rain and sun”. This need for protection during the ‘seasoning’ process suggests that opencast quarrying for Reigate Stone would render the stone unsuitable for building purposes. This is, of course, entirely consistent with the observation made in section 2.1 above that naturally weathered outcrops are too friable to be used in buildings.

Once underground, quarrying was continued by tunnelling beneath the ‘roofstone’ layer. To begin with, two tunnels would be cut; one would run obliquely down the dip (e.g. c.5°NE at Merstham) and the other would cut across it roughly at right angles. As this second tunnel was extended, further down-dip passages would be cut roughly parallel to the first. In a few cases (e.g. Tower Wood Quarry, Fig 4) small connecting passages would be cut between adjacent down-dip quarry passages.

However, modern surveys of the quarries at Merstham/Chaldon and Godstone (see e.g. Fig 5) show that generally almost all of the dividing wall between passages was excavated leaving only pillars of stone in place to support the roof. This technique is often referred to as ‘pillar and stall mining’.

In all of the quarries investigated, the stone was cut using the simplest of hand tools: picks and wedges. Pick-marks are to be seen everywhere on the roof and on the in situ pillars. When the quarries finished working the working faces were left in various states of development some of which are shown below in Plates 1-3.

In all of the quarries investigated, the stone was cut using the simplest of hand tools: picks and wedges. Pick-marks are to be seen everywhere on the roof and on the in situ pillars. When the quarries finished working the working faces were left in various states of development some of which are shown below in Plates 1-3.

Careful study of the working faces has provided evidence of the sequence and techniques used to extract individual blocks of stone.

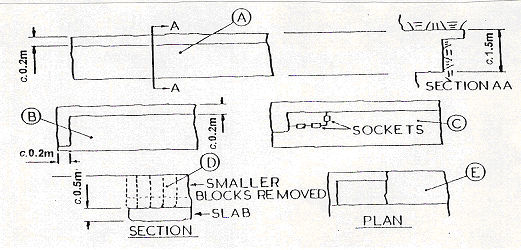

First (Fig 6a), a slot about 0.2m deep was cut with a pick along the whole length of the face, beneath the roofstone.

Next (Fig 6b), another slot was cut down one side of the face. This did not extend to the full depth of the face. Narrow, but deep, grooves were then picked out along the other two side of the intended block (Fig 6c) and squarebased sockets cut, again with a pick, at intervals along these grooves. These sockets are generally called ‘wedgepits’ (see e.g. Stanier,2000,p23). Iron wedges were then inserted into these wedge-pits and hammered home causing the stone to split at right angles with respect to the bedding. The blocks were then levered or lifted away. This procedure was repeated across the face, possibly a number of times, until only a large slab was left at the bottom of the face (Fig 6d). With the smaller blocks removed, a slot was then be cut around the back of this large slab (Fig 6e).

Next (Fig 6b), another slot was cut down one side of the face. This did not extend to the full depth of the face. Narrow, but deep, grooves were then picked out along the other two side of the intended block (Fig 6c) and squarebased sockets cut, again with a pick, at intervals along these grooves. These sockets are generally called ‘wedgepits’ (see e.g. Stanier,2000,p23). Iron wedges were then inserted into these wedge-pits and hammered home causing the stone to split at right angles with respect to the bedding. The blocks were then levered or lifted away. This procedure was repeated across the face, possibly a number of times, until only a large slab was left at the bottom of the face (Fig 6d). With the smaller blocks removed, a slot was then be cut around the back of this large slab (Fig 6e).

Wedges were then driven in at the base to shear the slab free. (Based on Croydon Caving Club,l976,pp2-3). The sole known example from the quarries at Chaldon of a line of wedge-pits is shown in Plate 4a. Plate 4b shows a wedge in situ at the bottom of this line. This is located in an area of roof-fall, which may explain why it was left.

A small number of the wedges used and a single example of a pick have been found in the quarries at Chaldon - see Plates 5 & 6 below. Wedges have been found in a number of sizes, from c.25xl5mm to c.50x30mm at the ‘head’ and from c.110mm to c.l40mm long. The pick measures 290mm along its greatest dimension

(Burgess,1987,p26).

2.2.3 Selecting the Stone.

As noted in 1.4 above, the beds seen in the currently accessible quarries at Merstham and Godstone appear to be a mixture of good building stone and poorer hearthstone in the form of lenses rather than simple alternating beds. Work is currently being undertaken so that “we might be able to tell the difference [between Reigate/building stone and hearthstone], and explain it in chemical and mineralogical terms” (Sowan,1999,p8). However, this will still leave unanswered the question: ‘How did the original quarrymen tell the difference?’ One possible answer is that they could ‘feel’ the difference as they picked into the rock, in the same way as archaeologists can sometimes feel a difference as they trowel across visually similar contexts. If this was the case one might expect to find different pick-mark densities in different parts of the quarries and indeed Sowan (ibid. p7) reports that in places “some indication of bedding demarcations c[an] be seen (better indicated by changes in the toolmarking than by the appearance of the stone itself)”. However the general impression one gets of the toolmarking in the quarries is that it is notable more for its uniformity than for its changeability.

As noted in 1.4 above, the beds seen in the currently accessible quarries at Merstham and Godstone appear to be a mixture of good building stone and poorer hearthstone in the form of lenses rather than simple alternating beds. Work is currently being undertaken so that “we might be able to tell the difference [between Reigate/building stone and hearthstone], and explain it in chemical and mineralogical terms” (Sowan,1999,p8). However, this will still leave unanswered the question: ‘How did the original quarrymen tell the difference?’ One possible answer is that they could ‘feel’ the difference as they picked into the rock, in the same way as archaeologists can sometimes feel a difference as they trowel across visually similar contexts. If this was the case one might expect to find different pick-mark densities in different parts of the quarries and indeed Sowan (ibid. p7) reports that in places “some indication of bedding demarcations c[an] be seen (better indicated by changes in the toolmarking than by the appearance of the stone itself)”. However the general impression one gets of the toolmarking in the quarries is that it is notable more for its uniformity than for its changeability.

Whilst there may be uncertainty about how the quarrymen distinguished between the building stone they wanted and the hearthstone, there is no doubt that they could make this distinction, and do so whilst working with minimal light underground. The waste material left underground is evidence of this. The amount is far too great to be explained solely in terms of waste chippings from squaring-up the blocks and, furthermore, some of the waste is in quite large pieces. The waste was placed to one side of the quarried out area, near to the face from which it came. It was usually retained behind dry-stone walls made from the larger pieces. Plate 7 (below) shows an example of such dry stone walling on the right; in the left fore-ground is the less commonly found situation in which the waste material has simply been piled up but not retained behind a stone wall. In both cases the waste material reaches to the roof, as it usually does, thus giving what were actually ‘pillar and stall mines’ (see 2.2.2 above) the appearance of a series of roughly parallel, dry-stone walled passages connecting

Whilst there may be uncertainty about how the quarrymen distinguished between the building stone they wanted and the hearthstone, there is no doubt that they could make this distinction, and do so whilst working with minimal light underground. The waste material left underground is evidence of this. The amount is far too great to be explained solely in terms of waste chippings from squaring-up the blocks and, furthermore, some of the waste is in quite large pieces. The waste was placed to one side of the quarried out area, near to the face from which it came. It was usually retained behind dry-stone walls made from the larger pieces. Plate 7 (below) shows an example of such dry stone walling on the right; in the left fore-ground is the less commonly found situation in which the waste material has simply been piled up but not retained behind a stone wall. In both cases the waste material reaches to the roof, as it usually does, thus giving what were actually ‘pillar and stall mines’ (see 2.2.2 above) the appearance of a series of roughly parallel, dry-stone walled passages connecting

the entrances with the working faces.

2.2.4 Moving the Stone Underground.

2.2.4 Moving the Stone Underground.

To get the cut blocks from the working faces to the entrances sledges or tucks were used. A seventeenth century account states:-

“Here [at Chaldon] are also two Free-Stone Quarries, from whose Meanders the Country People pretend they draw Stone with their Oxen and Hurdles for above half a Mile.” (Aubrey,1718,ii,p93)

No actual remains of ‘hurdles’ have been reported from quarries at Chaldon but there is evidence of grooves in the floors in some areas - see Plate 8. The grooves are “up to 4ins [100mm] wide and about 2ft [0.6m] apart”(Croydon Caving Club,1976,p21).

No actual remains of ‘hurdles’ have been reported from quarries at Chaldon but there is evidence of grooves in the floors in some areas - see Plate 8. The grooves are “up to 4ins [100mm] wide and about 2ft [0.6m] apart”(Croydon Caving Club,1976,p21).

Occasional finds of horse- as well as ox-shoes - show that both animals were used in the quarries.

Ox Shoe (l) and Pony Shoe (r), Chaldon Quarry

There are even the skeletal remains of both an ox and a pony - Plate 10. However explaining their presence in the Pony Skeleton, Chaldon Quarry quarry is difficult: From their locations underground it is unlikely that they are the remains of animals which just wandered into an abandoned open quarry entrance. On the other hand putrefying corpses would not have been tolerable in a working quarry. One possibility is that they were considered to be of no more use, and therefore killed, when the quarry closed. But the skull of the pony, which can be clearly seen in Plate 10, shows no sign of it having been pole-axed.

At Quarry Dean, Merstham and Godstone quarries, which were working in the 19th century, there is evidence of early use of iron plate railways to move the stone underground (Osborne,1982,p79). The role of the Surrey Iron Railway and its extension the Croydon Merstham and Godstone Railway, both of which were plate-railways, in transporting Reigate Stone to London is discussed in section 3.3.3 below.

At Quarry Dean, Merstham and Godstone quarries, which were working in the 19th century, there is evidence of early use of iron plate railways to move the stone underground (Osborne,1982,p79). The role of the Surrey Iron Railway and its extension the Croydon Merstham and Godstone Railway, both of which were plate-railways, in transporting Reigate Stone to London is discussed in section 3.3.3 below.

2.3 Dating the Quarries.

Direct dating of the known Reigate Stone quarries from their physical remains is extremely difficult for a number of reasons. One of these is the slow rate of development of quarrying techniques. As Stanier (2000,p2l) observes:-

“The basic techniques for quarrying and working freestones remained largely the same from Roman times until the early twentieth century. A quarrier or stone mason of the first half of the twentieth century would have been familiar with the workplace and working conditions of a Roman, and vice versa.”

“The basic techniques for quarrying and working freestones remained largely the same from Roman times until the early twentieth century. A quarrier or stone mason of the first half of the twentieth century would have been familiar with the workplace and working conditions of a Roman, and vice versa.”

Hence, although “Roman quarrying tools ... have been found from London to Housesteads on Hadrian’s Wall” (ibid.) they include things which are not markedly different from the pick and wedges shown in plates 5&6 above. There are even examples of wedge-pits attributed to Roman quarriers, including “a line of three wedge holes cut parallel with vertical joint in the rock face at Barcombe Down, overlooking the Stanegate fort of Vindolanda” (ibid.p3l). Furthermore, “in Devon, Beerstone from the chalk formation is said to have been quarried underground by the Romans” (ibid.p13, my emphasis).

The first improvement in quarrying techniques which was applied to many different types of rock did not occur until c.1800. This was “an easier and more accurate development of th[e wedge-pit and wedge] technique [which involved] the boring of a line of smaller holes for the insertion of ‘plugs’ and ‘feathers’. The steel feathers of half round section protect the stone from damage, spread the pressure evenly and help prevent the plug (wedge) from hitting the bottom of the hole and springing out dangerously when struck by a sledge hammer ... Th[is] method was introduced from the early nineteenth century onwards and continues today, the only difference being that the holes are now made by compressed air drills.” (ibid.p23). However there is no evidence in the form of signs of ‘bored’ holes or finds of ‘feathers’ of this technique being used in any of the known Reigate stone quarries; not even in those which were certainly worked in the nineteenth century, such as some at Godstone. Nor is there any evidence for the use of compressed air or other powered tools. Regrettably, these absences cannot be taken as indication of the antiquity of these quarries since “wedge-pits were used into the twentieth century” (ibid.).

The first improvement in quarrying techniques which was applied to many different types of rock did not occur until c.1800. This was “an easier and more accurate development of th[e wedge-pit and wedge] technique [which involved] the boring of a line of smaller holes for the insertion of ‘plugs’ and ‘feathers’. The steel feathers of half round section protect the stone from damage, spread the pressure evenly and help prevent the plug (wedge) from hitting the bottom of the hole and springing out dangerously when struck by a sledge hammer ... Th[is] method was introduced from the early nineteenth century onwards and continues today, the only difference being that the holes are now made by compressed air drills.” (ibid.p23). However there is no evidence in the form of signs of ‘bored’ holes or finds of ‘feathers’ of this technique being used in any of the known Reigate stone quarries; not even in those which were certainly worked in the nineteenth century, such as some at Godstone. Nor is there any evidence for the use of compressed air or other powered tools. Regrettably, these absences cannot be taken as indication of the antiquity of these quarries since “wedge-pits were used into the twentieth century” (ibid.).

A further problem with dating underground quarries stems from the fact that “mining is a destructive industry and each succeeding generation of miners erases the evidence of its predecessors as it extends their workings” (Barnes,1979,p45). The significance of this observation can clearly be seen by considering the simplest form of relative dating applicable to an underground Reigate Stone quarry: the entrance must pre-date the working faces.

However, as shown in 2. 2 . 2 above, much of the entrance area will have been filled up with waste stone and that which is still open will have been used continually for access to and from the working face(s). Hence anything found on the surface in an entrance ‘passage’ may date from any time between the date when the passage was first dug to the time it was last used.

This means that the few dateable artefacts which have been recovered, usually by cavers, and reported cannot be treated as if they were from secure, sealed and stratified contexts. However, taken with other evidence, they may provide some indication of when the quarries were open. For example, eighteenth century clay tobacco 18th Century Tobacco Pipes, Chaldon Quarry pipes - Plate 11 - correlate with graffiti chalked on the walls in contemporary handwriting - Plate 12. There is, of course, Graffito with Date (1723); Chaldon Quarry no certainty that either the writers or smokers were quarrymen. In fact Sowan (1975,p583) speculates that “these apparently casual visitors were prompted to explore the Chaldon mines by reading Aubrey’s brief mention of them!” The brief mention by Aubrey to which he refers is that quoted in 2.2.4 above.

This means that the few dateable artefacts which have been recovered, usually by cavers, and reported cannot be treated as if they were from secure, sealed and stratified contexts. However, taken with other evidence, they may provide some indication of when the quarries were open. For example, eighteenth century clay tobacco 18th Century Tobacco Pipes, Chaldon Quarry pipes - Plate 11 - correlate with graffiti chalked on the walls in contemporary handwriting - Plate 12. There is, of course, Graffito with Date (1723); Chaldon Quarry no certainty that either the writers or smokers were quarrymen. In fact Sowan (1975,p583) speculates that “these apparently casual visitors were prompted to explore the Chaldon mines by reading Aubrey’s brief mention of them!” The brief mention by Aubrey to which he refers is that quoted in 2.2.4 above.

The oldest dated find came from an area of quarry close to the boundary between Merstham and Chaldon. It was a mid-16th century jug - Fig 7 and Plate 13 - which was found near to one of the working faces. It was dated by John Clark of the Museum of London who suggested that it might be London made with Dutch influence or possibly an import from Holland. His analysis was based on comparison with examples found in excavations at Arundel House in the Strand in 1972 (see Haslam,1975,p227). Mid-16th Century Jug; Merstham/Chaldon Quarry.

Although not from a sealed context, the jug’s location, next to a working face, might indicate when work ceased in this part of the quarry. Certainly records of purchases of Reigate Stone become rarer in the mid-16th century. This is discussed further in 4.3.4 below.

Although not from a sealed context, the jug’s location, next to a working face, might indicate when work ceased in this part of the quarry. Certainly records of purchases of Reigate Stone become rarer in the mid-16th century. This is discussed further in 4.3.4 below.

The difficulty in determining dates for quarries provides one reason for wanting to be able to establish petrological links between buildings of known date and particular quarries. However, as is noted in 1.4 above, attempts to do this for Reigate Stone have had only limited success. Although “Exact sourcing of the greensand is virtually impossible ... [some specimens] appear to derive from a lower horizon in the greensand beds than [others]” (Samuel,1997,p195). The significance of this depends on where the two horizons lie. As Table 1 shows, it is possible to have two separate beds of Reigate Stone within a single quarried bed of Upper Greensand. In such a case each and every advance of the working face - see Fig 6 - would remove both beds more or less simultaneously. Hence, one cannot infer that stones from the higher bed were necessarily quarried before those from the lower bed, or vice versa.

According to Stanier “much has been written on building stones, and the examination of tool marks and other textures may be instructive in dating worked stones” (Stanier,2000,p33). However this technique is not generally applied to quarries for the simple reason that “such [tool]marks are extremely rare in quarries” (ibid.). Whilst this may be so in open-pit quarries it is clearly untrue of underground Reigate Stone quarries, as many of the plates in this account demonstrate. The reason for toolmarks not having been studied in these quarries is probably simply because no one with the necessary expertise has visited them. Having said that, my inexpert impression is that all of the marks seen underground could have been made with the sort of tools shown in Plates 5& 6 and may therefore not provide useful dating evidence.

According to Stanier “much has been written on building stones, and the examination of tool marks and other textures may be instructive in dating worked stones” (Stanier,2000,p33). However this technique is not generally applied to quarries for the simple reason that “such [tool]marks are extremely rare in quarries” (ibid.). Whilst this may be so in open-pit quarries it is clearly untrue of underground Reigate Stone quarries, as many of the plates in this account demonstrate. The reason for toolmarks not having been studied in these quarries is probably simply because no one with the necessary expertise has visited them. Having said that, my inexpert impression is that all of the marks seen underground could have been made with the sort of tools shown in Plates 5& 6 and may therefore not provide useful dating evidence.

Although there are many historical records, mainly in the form of building accounts, which give details of the purchase and use of Reigate Stone, there are few before the nineteenth century which include any details about the quarries. Domesday Book includes only seven quarries for the whole country (although there are reasons for believing that it under-records the true number) (ibid.p15). Two of these seven are in Limpsfield, c.4km east of Godstone. The VCH (ii,p277) asserts that these were undoubtedly for Reigate Stone. Turner (1995,p285), however, states that “it is not certain that these were Upper Greensand quarries”; a view supported by geological considerations - see 1.4 above.

Although there are many historical records, mainly in the form of building accounts, which give details of the purchase and use of Reigate Stone, there are few before the nineteenth century which include any details about the quarries. Domesday Book includes only seven quarries for the whole country (although there are reasons for believing that it under-records the true number) (ibid.p15). Two of these seven are in Limpsfield, c.4km east of Godstone. The VCH (ii,p277) asserts that these were undoubtedly for Reigate Stone. Turner (1995,p285), however, states that “it is not certain that these were Upper Greensand quarries”; a view supported by geological considerations - see 1.4 above.

The most explicit medieval document regarding Reigate stone quarries is the charter of 1218 quoted in 2.1 above. A Patent of Edward III (cited in VCH,ii,p277) appointed John and Philip Prophet masters of the quarries at Merstham and Chaldon in 1359. How this might relate to specific quarries is discussed further in 3. 1 below. Other medieval documents similarly locate quarries no more precisely than to a particular parish and are therefore of limited use in dating individual quarries. Even as late as the end of the seventeenth century Aubrey (pub.1718) provides no more locational detail than that there were working Reigate Stone quarries in Gatton, Chaldon, Bletchingley, and Godstone. Contemporary documentation relating specifically to quarrying can be found from the nineteenth century onwards, although even this is not necessarily comprehensive.

The most explicit medieval document regarding Reigate stone quarries is the charter of 1218 quoted in 2.1 above. A Patent of Edward III (cited in VCH,ii,p277) appointed John and Philip Prophet masters of the quarries at Merstham and Chaldon in 1359. How this might relate to specific quarries is discussed further in 3. 1 below. Other medieval documents similarly locate quarries no more precisely than to a particular parish and are therefore of limited use in dating individual quarries. Even as late as the end of the seventeenth century Aubrey (pub.1718) provides no more locational detail than that there were working Reigate Stone quarries in Gatton, Chaldon, Bletchingley, and Godstone. Contemporary documentation relating specifically to quarrying can be found from the nineteenth century onwards, although even this is not necessarily comprehensive.

Part 2, covering the distribution and use in buildings of Reigate stone, together with a full bibliography, will appear in Pelobates 88.

Acknowledgments

I wish to thank the following people for the advice and assistance that they gave me whilst I was working on this dissertation:-

- Mr Harvey Sheldon; Course Director MA Archaeology,

- Birkbeck College; for reviewing and discussing the initial proposals for this dissertation; for helpful comments on an early draft of the first two sections of it; and for effecting an introduction to Dr Mark Samuel.

- Dr Mark Samuel; Architectural Masonry Archaeologist, Museum of London Specialist Services; for an informative discussion on the subject of Reigate Stone generally; for providing copies of relevant papers; and particularly for providing me with a copy of his extensive bibliography of medieval masonry building technology.

- Mr James Drummond-Murray; Museum of London Archaeology Service; for providing information over the telephone about the finds of Reigate Stone in pre-Boudiccan levels in his excavations at Borough High Street.

- English Heritage staff at the National Monuments Record Enquiry and Research Services for carrying out a number of searches of the computerised NMR database at my request.

- Mr Paul Sowan for an informative discussion following presentation of his lecture on Reigate Stone at the South East Regional Industrial Archaeology Conference 2000.

- Mrs Sarah Pankiewicz; librarian of the Croydon Caving Club; for providing many documents which would otherwise have been unobtainable; and particularly for providing the slides taken by Mr Frank Thompson in 1977 from which all of the plates in this dissertation, except Plate 15, were taken.